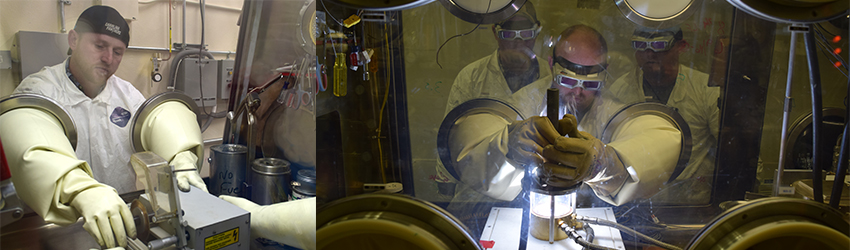

Instrument Description

The AFCI glovebox, located inside of the Fuel Manufacturing Facility, is used for transuranic fuel fabrication activities. The glovebox windows and gloves are shielded to provide radiological dose reduction. It is maintained under an atmosphere of purified argon, helium, or a mixture of argon or helium, to levels of <10 ppm oxygen. Glovebox equipment includes standard powder processing equipment, such as a high-energy ball mill, press, and high-temperature tantalum element vacuum furnace. In addition to powder processing equipment, there are horizontal and vertical tube furnaces, which can be used in a vacuum, hydrogen, argon, or wet argon environment and a Centorr Series 5SA arc melter. Co-located with the AFCI glovebox is an X-ray radiography system. The system is composed of a 160 KeV X-ray tube, and images can be captured and processed digitally.

Applications

The AFCI glovebox is used to fabricate metallic and ceramic fuel forms, as well as to provide an inert environment for sample preparation and fuel irradiation test assembly. Samples can be fabricated, encapsulated in cladding tubes, and removed from the glovebox line with no external contamination.

The Centorr 5SA arc melting is ideal for transuranic alloy production on the scale of 10-50 grams, and casting simple shapes that can be incorporated into fuel irradiation test. A vertical tube furnace is currently configured to americium purification through distillation but can be configured for a number of different applications. The powder processing equipment, including the high-temperature vacuum furnace, can be used for ceramic fuel fabrication or similar powder metallurgy processes. A horizontal standard tube furnace can also be used for powder processing.

The radiography system is routinely used for weld radiography as part of fuel irradiation test assembly. However, it can also be used to radiograph any number of clad radiological items, for example, small shipping containers, storage cans, etc.